Cleanroom News, Electronics Assembly

Different Sources of Contamination within the Cleanroom

When it comes to maintaining the critical nature of a cleanroom, vigilance is key. Understanding the various sources of contamination is paramount in ensuring the integrity of your operation and the tasks performed within. Let’s delve into the depths of cleanroom contamination and uncover the hidden culprits that can compromise your controlled environment.

Particulate Contamination: The Visible Threat

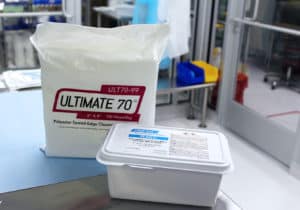

Particulate contamination consists of tiny particles suspended in the air, ranging from dust and skin flakes to microorganisms. These particles can easily infiltrate cleanrooms through air filtration systems, clothing, or even the movement of personnel. Controlling particulate contamination within a cleanroom requires a multifaceted approach including using products specifically designed to help control and minimize particulate contamination.

Cleanroom Products for Controlling Particulate Contamination

Static Contamination: The Silent Disruptor

Static electricity can attract and hold onto particles, leading to an increase in contamination levels within the cleanroom. This phenomenon can be particularly problematic in environments where sensitive electronics or materials are present. Mitigating static contamination requires the use of anti-static materials and grounding techniques to neutralize static charges.

Top Products for Controlled Static Contamination:

Chemical Contamination: The Invisible Intruder

Chemical contamination can arise from a variety of sources, including cleaning agents, solvents, and off-gassing from materials within the cleanroom. These contaminants can compromise the integrity of sensitive processes and products, making it essential to monitor and control chemical exposure within the cleanroom environment.

Products for Reducing Chemical Contamination:

- Chemical Storage Cabinets

- HEPA Filters

- Surface Protection and Absorption Pads

Cross-Contamination: The Traveling Trespasser

Cross-contamination occurs when contaminants from one area or source are transferred to another. This can occur through various means, such as personnel movement, equipment transfer, or airflow patterns. Preventing cross-contamination requires strict adherence to cleanroom protocols and the use of barriers to prevent the spread of contaminants.

Products for Reducing Cross-Contamination:

- Tacky Floor Mats

- Cleanroom Wipe Dispensers

- Cleanroom Apparel

- Tacky Rollers

- Pass-Through Chambers

- Airlocks

- Dedicated Tools and Cleanroom Storage

Microbial Sporulation: The Persistent Peril

Microbial sporulation refers to the formation of spores by certain types of microorganisms, such as bacteria and fungi. These spores are highly resistant to environmental stresses, making them a persistent threat in cleanroom environments. Controlling microbial sporulation requires the implementation of robust sterilization protocols and the use of antimicrobial agents.

Products for Reducing Microbial Sporulation:

- Antimicrobial Cleaners

- Disinfectants

- Sterilization Equipment

- Air Filtration Systems

- Sterile Garments

- Biocidal agents

- Regular Cleaning with Cleanroom Wipes

In conclusion, maintaining a cleanroom environment free from contamination requires a comprehensive understanding of the various sources of contamination. By addressing these sources through rigorous cleanliness protocols and effective contamination control measures, you can ensure the integrity of your cleanroom and the quality of your products and processes.

Always follow your specific cleanroom or company procedural manual before this guide.