Cleanroom News, Electronics Assembly, General Topics

Get to Know Your PCB Printer Stencil Wiping Roll

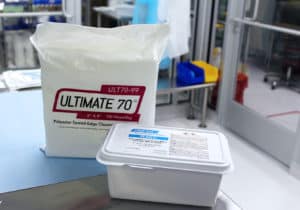

Lint-Free Stencil Roll Material

While no material is entirely lint-free, there are materials that are virtually lint-free. This is an important attribute to look for in your stencil wiping roll. Contaminated PC boards are a common problem. While the contamination itself is often thought of as a mystery to the printer operator, the cause may come from the stencil wiping roll. This is largely due to the sticky solder paste and sharp edges of the stencil’s apertures.

The stencil wiping roll is supposed to clean the stencil in an attempt to prevent contamination. However, some stencil wiping rolls leave behind pieces of its material on the stencil, subsequently contaminating the PC board. When these contaminants pass through the oven, voids will occur.

Selecting a stencil cleaning roll such as the GREEN MONSTER! can help prevent damage to products, parts, and expensive equipment. GREEN MONSTER is free of weak linty paper fibers because it is comprised of coarse rayon and ESD polyester bonded by a tough proprietary formula of copolymers.

View or Download Green Monster Stencil Wiping Rolls Brochure

One can determine the probability of contamination with an easy test of the stencil wiping roll. The test is called the “Tape Test”. It is a quick and simple experiment that will save any company money by not having to repair contaminated boards. It will also help any company in determining which stencil wiping rolls are acceptable.

Tape Test Procedure

- First, cut off a piece of scotch tape or black electrical tape about 2 inches in length.

- Place the strip of tape along the surface of the stencil wiping fabric.

- Once the tape has adhered to the surface, pressure must be applied. The pressure should be applied in an even fashion. To ensure that the pressure is equally applied roll a 1,000gm calibration weight over the taped surface. If a weight of this size is not available, a seam pro (used for wallpaper seam attachment), a full can of soda or any tool that will provide equal weight distribution can be used. In some cases, simply using a finger will be acceptable.

- If Scotch tape is used, place it on a black surface and observe the mount of fibers pulled off with the naked eye or better yet a magnifier. This test can easily be quantified by counting fibers and particles under magnification.

- For the best determination, repeat this step for front and back sides of the wiping roll’s fabric.

Important: This test is only valid when comparing fabrics.

The Importance of ESD Safe Stencil Wiping Rolls

A little known but important attribute of a high-quality stencil roll are it’s ESD attributes. This is critical in preventing ESD events that could damage components, cause voids in solder traces and possible explosions in the presence of flammable solvent vapors. The mere action of re-rolling typical white paper rolls during its manufacturing process creates huge amounts of static. After spending so much time, money and effort in creating an ESD safe assembly area, why would anyone want to bring in a paper roll that is sizzling with static? Worse yet, placing it right next to an ESD sensitive PCB! The GREEN MONSTER! is a drop-in, ESD-safe solution for any static generating rolls you are currently using.

CFM Porosity for Vacuum Optimization

The fiber composition of GREEN MONSTER! is designed to provide the correct amount of porosity. This allows maximum utilization of the vacuum system on-screen printers. Consequently, solder paste vacuuming and removal from apertures is “fierce” and extremely efficient. See for yourself by blowing through our fabric, then try to blow through a regular paper roll material. More air will pass through the GREEN MONSTER! roll; proving it’s higher vacuum efficiency.

For more tips on optimizing your PCB cleaning process, please contact us.