Cleanroom News, General Topics

How To Determine the Cleanliness of a Wipe

Several factors help determine the cleanliness of a wipe. Much like resolution and refresh rate help verify the quality of a television, cleanroom wipes also have technical indicators that can be measured to help gauge their effectiveness in a controlled environment. A wipe’s “cleanliness” is measured by four unique factors: particle count, fiber count, non-volatile residue (NVR), and ION content.

1 & 2. Particle & Fiber Count

Several tests can be done to measure a wipe’s releasable particles and fiber count. The following three cleanliness indicators can be used to measure these important properties:

Particle Generation / Biaxial Shake Test — A wiper is “washed” in water, using a biaxial shaker, for 5 minutes. A liquid-borne particle counter then tallies the particles that are released into the water. Dividing the total number of particles that are released by the area of the wiper gives results expressed as particles ≥ 0.5µm per square cm of the wiper. [IEST-RP.CC004.3, Section 6.1.3]

Fiber Test — Using a biaxial shaker, a wiper is “washed” in water for 5 minutes. Fibers released into the water are filtered onto a membrane and they are counted microscopically. Results are expressed as fibers ≥ 100µm per square cm of the wiper. [IEST-RP.CC004.3, Section 6.2.2.2]

Airborne Particle / Helmke Drum Test — Under controlled conditions, 10 wipers are tumbled in a rotating drum to release any particles from the wiper fabric. An airborne particle counter is used to count released particles. These results are expressed as the number of particles per wiper per cubic ft of air sampled. [IEST-RP-CC003.4 Section B2.5]

3. Non-volatile residue (NVR)

A popular method for testing NVR (non-volatile residue) extractables from a wipe is using DI water (deionized water) and 2-Propanol (IPA). For this test, the wiper is immersed in the solvent and removed. The remaining liquid is filtered and evaporated; at which time the NVR is calculated. The results are stated in grams of extracted materials per square meter of the wiper. High-Tech Conversions uses the following method to test NVR: DIW Extractant, 100 mL DI water at ambient temp for 24 hours

4. Metallic Ions

Ions are extracted in deionized water. They are quantitatively analyzed by Ion Chromatography. Results are expressed in parts per million (ppm). [IEST-RP.CC004.3, Section 7.2.2]

Common metallic elements measured are Calcium (Ca), Potassium (K), Sodium (Na), and Chloride (Cl).

Other Important Considerations

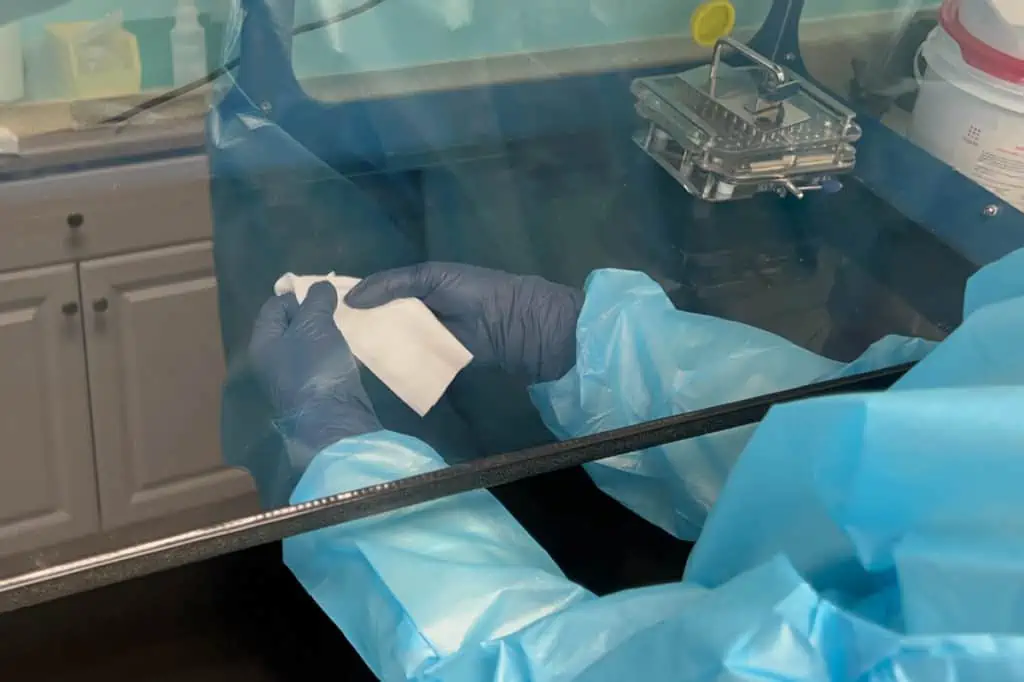

Manufacturing

Understanding the manufacturing and production processes of a cleanroom wipe is critical in determining its quality. Consider the reputation of the company producing the wipe. Have they been around a long time? Can they provide quality assurance and the necessary documentation to accompany each wipe? Are they outsourcing production, or do they have full control of the process? Lastly, and quite possibly most importantly, are they manufactured and packaged in a cleanroom?

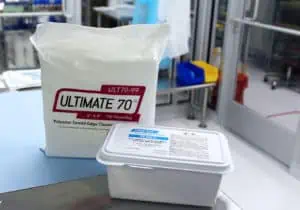

Packaging

Packaging is something that should not be overlooked. Anything that is used within the cleanroom should be packaged appropriately. In many cases, this means being packaged with two bags, or double-bagged. This is because some protocols require outer packaging to be removed immediately before the product enters the cleanroom.

Labels or any other sticker labeling should be made of non-shedding materials such as polyester or polypropylene. Paper labels are not acceptable if the product packaging is brought into the cleanroom.

Final Thoughts

At High-Tech Conversions, our wipes are made from the highest quality substrates and manufactured in a critically controlled environment. They are double bagged and featured cleanroom compatible packaging. Many of our wiping products are made at our facility in Enfield, Connecticut. We have over 25 years of experience producing the highest quality cleanroom supplies available.

For more information, including recommended products for your specific controlled environment, contact us today.