Cleanroom News, General Topics

3 Ways To Prevent Cleanroom Contamination

Cleanrooms play a critical role in various industries, necessitating strict adherence to contamination prevention measures. Ensure your controlled environment remains suitable in your industry by following these three tips to prevent cleanroom contamination.

Proper Training for Cleanroom Protocols

Proper training of employees working in cleanrooms is paramount to maintaining a contamination-free environment. When employees understand and adhere to cleanroom protocols, the risk of contaminants entering or spreading within the controlled space is minimized. This ensures that the products being manufactured, tested, or assembled in the cleanroom remain free from contamination. Consider implementing signage reiterating essential protocols throughout the cleanroom environment to reinforce your best practices daily.

Examples of cleanroom protocols include thorough handwashing, correct gowning procedures, and the proper use of gloves, masks, and other personal protective equipment (PPE). Employees should also be trained on how to safely enter and exit the cleanroom and the appropriate handling and disposal of waste materials. Furthermore, training should include understanding cleanroom classifications and the specific requirements for each category. This knowledge will empower employees to take ownership of their actions and make informed decisions, ensuring the cleanroom environment remains uncompromised, and the desired level of cleanliness is consistently maintained.

Cleanroom Maintenance and Cleaning Best Practices

Of course, knowing how to act while in your controlled environment is only part of the puzzle—preventing cleanroom contamination requires proper cleaning and maintenance habits. Regular maintenance helps identify potential contamination sources, while cleaning ensures that any contaminants are effectively removed. To uphold the highest standards of cleanliness, it is essential to follow best practices and use appropriate tools and techniques for cleanroom maintenance and cleaning. Furthermore, establish a cleaning schedule that includes daily, weekly, and monthly tasks, as well as periodic deep cleaning. This ensures that all surfaces, equipment, and air filtration systems are consistently maintained at an optimal level of cleanliness.

One helpful resource for cleanroom maintenance is the Institute of Environmental Sciences and Technology (IEST) ISO 14644 guidelines, which provide detailed information on cleaning procedures, frequency, and documentation. Adhering to these guidelines helps ensure that your cleanroom complies with industry standards. Or feel free to contact our experienced and knowledgeable team at High Tech Conversions for assistance regarding proper cleanroom maintenance and cleaning procedures!

Investing in Quality Cleanroom Supplies

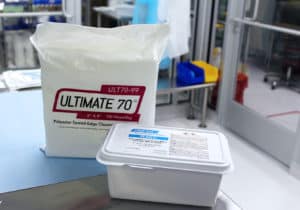

Investing in high-quality cleanroom supplies is essential for maintaining a controlled environment and preventing contamination. Using reliable and proven products ensures that your cleanroom remains compliant with industry standards and operates at peak efficiency. One example of a quality cleanroom supply is presaturated cleanroom wipes, which are designed to effectively remove contaminants from surfaces without generating additional particles or residues. These wipes offer a convenient and efficient solution for routine cleaning tasks, as they come pre-moistened with the appropriate cleaning agents, eliminating the need for additional spraying or dipping. Other essential cleanroom supplies include HEPA-filtered vacuums, lint-free gloves, and properly designed garments that minimize particle release.

Implementing proper training, adhering to maintenance and cleaning best practices, and investing in quality cleanroom supplies are some of the many ways to prevent cleanroom contamination. Contact our friendly team today at High Tech Conversions to learn more about enhancing the quality of your controlled environment.