Cleanroom News, General Topics

The Ultimate Guide to Cleanroom Wipers: Key Things To Know

Navigating the world of cleanroom wipers can be daunting, given the wide range of products and applications they serve. In our ultimate guide, we’ll explore the key things you need to know about cleanroom wipers, helping you make informed decisions and maintain the highest standards of cleanliness in your controlled environment.

Cleanroom vs. Standard Cleaning Wipers

Cleanroom wipes and standard cleaning wipes serve different purposes and are designed to meet the specific needs of their respective applications. As the name suggests, cleanroom wipes are specifically engineered for use in controlled environments such as laboratories, pharmaceutical manufacturing facilities, and semiconductor fabrication plants. These wipes are made from materials with low particle generation and low levels of chemical extractability, ensuring minimal contamination during the cleaning process. They also undergo stringent quality control measures, including testing for particle counts, fibers, and ions, to determine their viability in a controlled environment.

On the other hand, standard cleaning wipes are intended for general-purpose cleaning tasks in everyday environments. These wipes are typically made from materials such as cellulose, polyester, or a blend of both, which may not be suitable for cleanroom applications due to their higher particle generation and potential for contamination. Standard cleaning wipes may also contain additives such as fragrances, surfactants, or preservatives, which could compromise the integrity of sensitive products or processes in a cleanroom setting. While these wipes may be effective for cleaning household surfaces or office equipment, they do not offer the same level of cleanliness and contamination control required for critical environments like cleanrooms.

Important Cleanroom Wiper Terms To Know

When shopping for cleanroom wipes, there are a few terms you should familiarize yourself with in order to make an informed decision about the product that best suits your needs.

Laundered: Laundered wipes are those that have undergone a specialized washing process in a controlled environment to remove any potential contaminants, such as particles, fibers, and residues. This process typically involves multiple cycles of washing, rinsing, and drying using ultra-pure water and specialized detergents. The end result is an extremely clean and consistent product, ensuring the wipe’s effectiveness in maintaining the cleanliness and integrity of your cleanroom environment.

Material Composition: Cleanroom wipes should be made from non-shedding, low-linting materials such as polyester, microfiber, cotton, or a blend of polyester and cellulose. These materials minimize particle generation and are compatible with cleanroom protocols. Certain materials can yield better results and compatibility with various cleaning agents and disinfectants.

Absorbency: Wipes used in a controlled environment should be comprised of substrates designed to effectively remove particulate matter and contaminants from surfaces. Each application may require a wiper with different levels of absorbency. For example, a sensitive surface such as an optical lens does not require a wipe with a high level of absorbency. Polyester wipes are typically ideal for that application. Spill control or soaking liquids will require a wipe with higher levels of absorbency such as nonwoven wipes which can be engineered with various poly-cellulose compositions.

Particulate Generation/Releasable Particles: Several tests can be done to measure a wipe’s releasable particles and fiber count. The following three cleanliness indicators can be used to measure these important properties: Particle Generation / Biaxial Shake Test [IEST-RP.CC004.3, Section 6.1.3], Fiber Test [IEST-RP.CC004.3, Section 6.2.2.2], Airborne Particle / Helmke Drum Test [IEST-RP-CC003.4 Section B2.5].

Related article: https://high-techconversions.com/how-to-determine-the-cleanliness-of-a-wipe/

Extractables: Cleanroom wipes should have low levels of extractable substances such as ions, chemicals, and solvents that can potentially contaminate the cleanroom environment or the surfaces being cleaned.

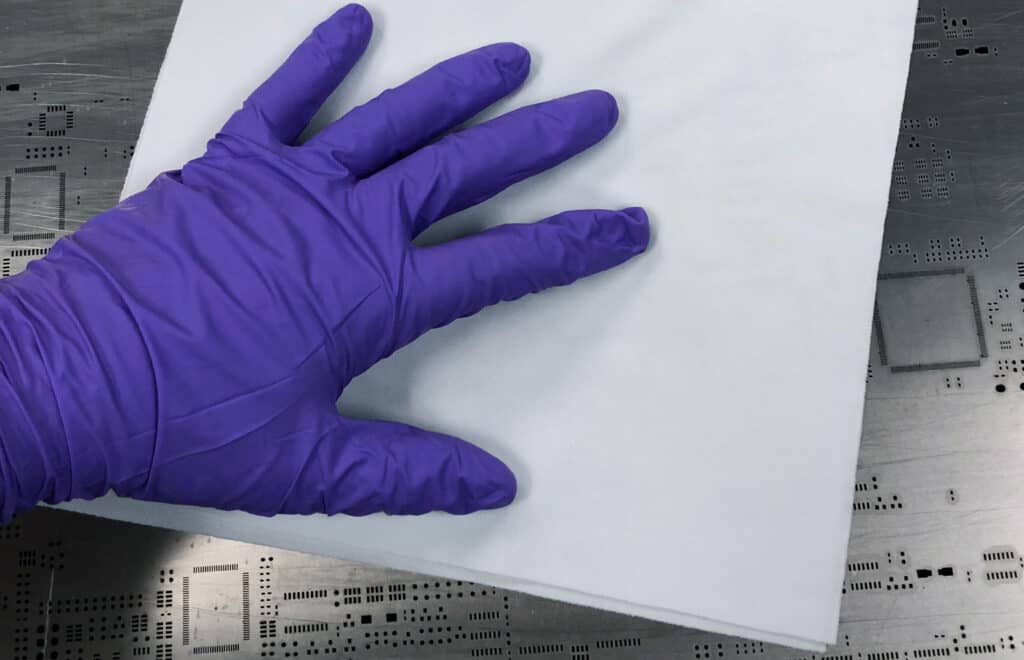

Sealed-Edges: Wipes used in ISO 5 (Class 100) – ISO 4 (Class 10) cleanrooms often have sealed or laser-cut edges to minimize fiber release and ensure clean, streak-free wiping. This prevents loose fibers from becoming airborne and reduces the risk of surface contamination.

Sterility: In certain cleanroom applications such as the compounding of pharmaceuticals, wipes may need to be sterile to maintain the integrity of the product and environment as well as compliance and/or industry standards. Sterile wipes undergo a specific sterilization process, such as gamma irradiation or ethylene oxide (EtO) treatment.

Cleanroom Packaged and Processed: Wipes used in cleanrooms should be packaged in a way that preserves their cleanliness and prevents contamination. Depending on the level or cleanroom they are designed for, they may come double bagged in resealable packaging, cleanroom-compatible dispensers, or individually sealed packages to maintain their integrity until use.

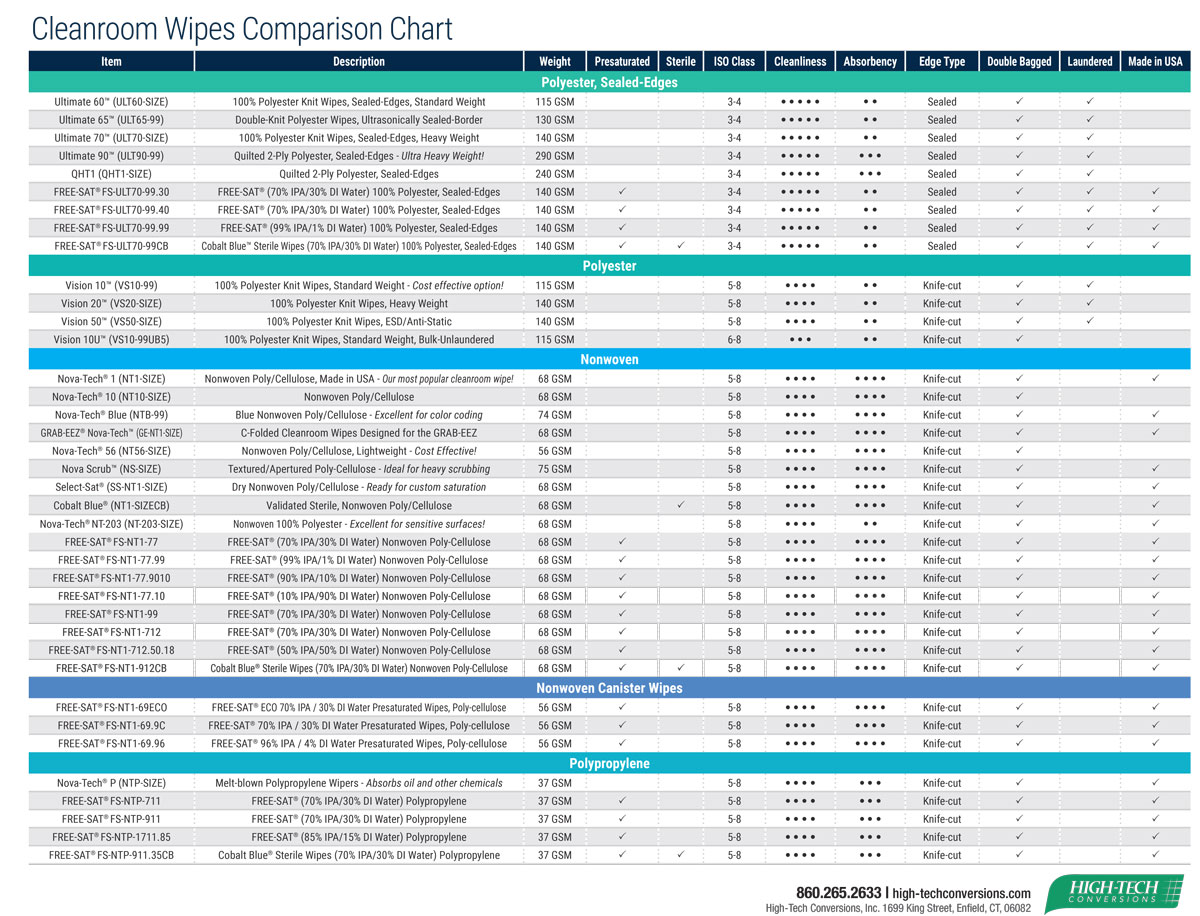

Different Cleanroom Wiper Product Types

In the world of cleanroom wipers, various product types are designed to cater to the specific needs of different cleanroom applications. High-Tech Conversions, for example, offers a diverse range of cleanroom wiper products to ensure optimal performance in various industries and environments. You can choose the most suitable option for your particular cleanroom requirements by understanding the available product types.

Among these product types are the NOVA-TECH™ Lint Free Wipes, which are made from a non-woven blend of polyester and cellulose fibers, providing excellent durability and absorbency. These wipes are ideal for spill control, cleaning, and maintenance in controlled environments. Another product type is the FOAMtec Wipers, which are constructed from open-cell polyurethane foam, offering excellent particle entrapment and retention capabilities. These wipes are particularly well-suited for applications requiring high cleanliness levels and low particle generation, such as in the semiconductor, pharmaceutical, and aerospace industries.

High-Tech Conversions also offers specialized products like the ESD Wipes, designed to provide static-dissipative properties for use in electrostatic-sensitive environments. By exploring these different cleanroom wiper product types, you can ensure you select the most appropriate solution for maintaining the stringent cleanliness standards required in your specific cleanroom application.

Cleanroom Wipes Across Various Industries

Cleanroom wipes are vital in maintaining the cleanliness and integrity of controlled environments across various industries. These industries have specific requirements and standards for contamination control, making the use of specialized cleanroom wipes essential for their operations. By understanding the diverse applications of cleanroom wipes, we can appreciate their importance in various sectors.

The semiconductor and electronics manufacturing sector is a major industry that relies heavily on cleanroom wipes. In these highly sensitive environments, even the smallest particles or contaminants can cause defects in delicate components, leading to product failure or reduced performance. Cleanroom wipes are used throughout the manufacturing process to remove impurities, dust, and residue from surfaces and equipment, ensuring the highest possible yield and quality of electronic components. Another important industry is the pharmaceutical and biotechnology sector, where cleanroom wipes are crucial for maintaining sterile conditions during drug production and research activities.

Contamination control in these settings can be a matter of life and death, directly impacting the safety and efficacy of medications and therapies. Other industries that depend on cleanroom wipes include aerospace, medical device manufacturing, and optical lens production, where precision, cleanliness, and reliability are paramount. In each of these industries, cleanroom wipes serve as a vital tool in upholding rigorous cleanliness standards and ensuring the success of the products and processes they support.

Understanding IPA Ratings

When shopping for cleanroom wipes, one important thing to look out for is the IPA (isopropyl alcohol) rating. This indicates how much alcohol is present on each wipe, a metric that can affect its efficacy when it comes to removing stubborn dirt or residue. Typical IPA ratings range from 50 to 99 percent, with higher IPA ratings generally indicating stronger disinfecting power. However, it’s important to check the manufacturer’s instructions, as high concentrations of alcohol can damage certain surfaces. The best way to determine which wipe is right for your needs is to test them in a small area first and see which works best.

No matter what industry you’re in, cleanroom wipes are essential for keeping your environment safe and free of contamination. With this ultimate guide in hand, you’ll have no trouble selecting the perfect wiper type for your business needs. Contact our friendly team at High Tech Conversions today for more key things to know about cleanroom wipes and to order the ideal products for your application!