Cleanroom News, General Topics

Contamination Control in the Cannabis Industry: A Critical Role for Cleanrooms and Quality Air

In the rapidly evolving cannabis industry, contamination control has emerged as a critical issue. From cultivation to product manufacturing, maintaining a clean, controlled environment is paramount to ensure the safety and quality of cannabis products. This article delves into the importance of contamination control, the role of cleanrooms and air quality in cannabis production, and the regulatory landscape governing cannabis products.

The Importance of Contamination Control in the Cannabis Industry

Contamination poses significant risks to the cannabis industry. It can lead to failed compliance testing, costly product recalls, and loss of consumer confidence1. Common contaminants include pesticides, heavy metals, microbial contaminants, and residual solvents.

Preventing contamination requires a multi-faceted approach that includes maintaining clean facilities, decontaminating equipment, and ensuring employees follow proper hygiene practices2. Cleanrooms play a pivotal role in this endeavor.

The Role of Cleanrooms and Controlled Environments in Cannabis Production

Cleanrooms are controlled environments specifically designed to minimize airborne particles, regulate temperature and humidity, and prevent contamination. They are integral to cannabis production due to their ability to control potential sources of contamination, including air particles, microorganisms, and chemical vapors.

In addition to maintaining a controlled environment, cleanrooms utilize various supplies to further enhance contamination control. Personal Protective Equipment (PPE), such as gloves, face masks, and cleanroom suits, are used to prevent human contaminants from entering the environment. Cleanroom wipers, made from materials designed to pick up and retain particles, are essential to keep surfaces free from contaminants.

Dressed for Success: PPE and Cleanroom Supplies in Cannabis Production

Contamination control isn’t just about the environment; it’s also about what cultivators wear and use. Personal Protective Equipment (PPE) and cleanroom supplies, carefully selected for their effectiveness, become the armor worn by those on the frontline of cannabis production.

From sterile gloves to full-body suits, every piece of PPE is a shield against potential contaminants. Cleanroom supplies ensure that every step of processing and production adheres to the highest hygiene standards.

Cultivators and processors often don full-body suits, complete with hoods and booties, creating a barrier between themselves and potential contaminants.

These suits are a shield against external elements that could compromise the product. Additionally, dedicated face shields or goggles are common, offering an extra layer of protection for the eyes.

Gloves are crucial in stages of cannabis production and testing. Nitrile gloves are a common choice in the cannabis industry due to their durability, flexibility, and resistance to a wide range of chemicals. These gloves are chosen not just for their protective qualities but also for their compatibility with the delicate tasks involved in cannabis cultivation.

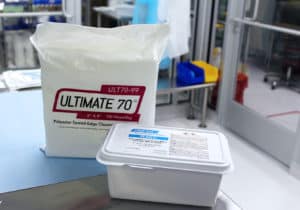

Cleanroom wipes, designed specifically for controlled environments, are used to gently and thoroughly clean surfaces, tools, and equipment. These wipes are engineered to trap and remove even the smallest particles, without introducing new contaminants. Before every critical step in the production and packaging process, cultivators use these wipes to ensure that surfaces are pristine, minimizing the risk of introducing unwanted elements to the cannabis ecosystem.

While the specifics may vary depending on state regulations and individual company protocols, the use of PPE and gloves is an integral part of cGMP in the cannabis industry, helping to ensure product safety and worker protection.

The Importance of Air Quality in Cannabis Cultivation

Air quality is another crucial aspect of contamination control in cannabis cultivation. Maintaining optimal air quality involves regulating temperature and humidity levels, as well as filtering out contaminants and pathogens3.

Air showers are a common feature in cleanrooms used for cannabis cultivation. These devices help prevent cross-contamination by removing harmful particles that may adhere to clothing, such as spores and mildew.

The FDA’s Role in Regulating Cannabis Products

The Food and Drug Administration (FDA) plays a significant role in the regulation of cannabis products. While the agency does not directly regulate the cultivation of cannabis, it is responsible for ensuring the safety and efficacy of cannabis-derived products, including cannabidiol (CBD).

FDA treats products containing cannabis or cannabis-derived compounds as it does any other FDA-regulated products — meaning they’re subject to the same authorities and requirements as FDA-regulated products containing any other substance4.

In conclusion, contamination control is vital to the integrity of the cannabis industry. By leveraging cleanroom technology and maintaining high-quality air, cannabis businesses can significantly reduce the risk of contamination, ensuring the production of safe, high-quality products.

Footnotes

- Keeping it Clean: Contamination Control in the Cannabis Industry

- Controlling Microbial Contamination in Cannabis

- The Importance of Air Quality in Cannabis Cultivation

- FDA Regulation of Cannabis and Cannabis-Derived Products