Cleanroom News, General Topics

How To Choose Industrial Cleaning Wipes for Your Application

Industrial cleaning wipes are an overlooked yet crucial tool in many industries, including automotive repair shops, food processing plants, and various manufacturing settings. These seemingly simple items are often the unsung heroes of cleanliness and help maintain a safe and productive work environment. Certain industrial cleaning wipes are used as disposable alternatives to traditional cleaning towels in non-sterile applications. These include cellulose-material shop towels that are perfect for cleaning up oil, grease, and other common spills in an auto shop or manufacturing floor. They offer a convenient and cost-effective solution to keeping workspaces clean and tidy.

On the other end of the spectrum are industrial cleaning wipes designed for non-critical environments. Among these, IPA industrial-grade alcohol wipes are commonly used to sanitize surfaces and equipment. Understanding the differences between sterile and non-sterile cleaning products does not simplify the purchasing process, however. Read on to learn how to choose industrial cleaning wipes for your specific application.

Industrial Cleaning Wipes

Industrial cleaning wipes are more than just pieces of cloth. They are specially designed and manufactured to cater to specific needs within various industries. To the untrained eye, they might look similar to household cleaning wipes, but the differences are significant and worth noting. Compared to standard household products, industrial cleaning wipes are usually low-lint, highly absorbent, and can remove a variety of chemicals from surfaces.

Quality is truly the backbone of effective industrial cleaning wipes. Many factors combine to determine the efficacy of these essential tools, each contributing a unique aspect to the overall performance of the wipe. The material of the wipe is a fundamental factor. Different materials offer varying levels of durability, absorbency, and chemical resistance. For instance, cellulose is known for its toughness and longevity, making it an excellent choice for heavy-duty cleaning tasks. Alternatively, microfiber boasts superior absorbency and is gentle on delicate surfaces, making it ideal for use in labs or electronics manufacturing.

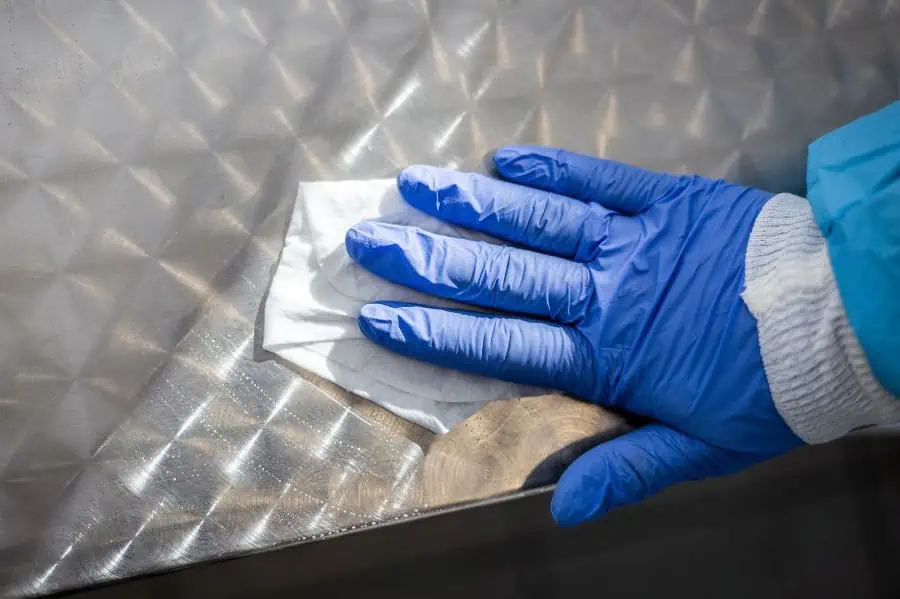

Absorbency is another crucial characteristic of industrial cleaning wipes. A highly absorbent wipe will quickly take up spills, preventing them from spreading and causing further damage. This feature is particularly important in industries that deal with liquid substances, such as oil in automotive workshops or chemicals in labs. The ability of a wipe to absorb and retain liquid efficiently can significantly improve cleanliness and safety in these environments. Chemical resistance is equally important, especially for tasks involving harsh solvents or corrosive substances. Wipes that disintegrate or leave residues when exposed to certain chemicals lead to contamination and pose safety risks. Therefore, an ideal industrial cleaning wipe must resist a wide range of chemicals to ensure it remains intact and functional, regardless of the cleaning task.

Lastly, linting is a critical aspect to consider. A low-lint wipe is essential in environments where cleanliness is paramount, such as automotive and aerospace manufacturing, food processing, and more. Any lint left behind can contaminate surfaces and, in some cases, interfere with the operation of machinery or equipment. A quality industrial cleaning wipe should generate minimal lint to maintain the integrity of the workspace. By understanding these characteristics, you can make informed decisions and choose the right wipes for your needs.

Cleaning Wipe Applications

Industrial cleaning wipes are utilized across a broad spectrum of industries, each with a unique set of cleanliness requirements and standards. From maintaining sterility in pharmaceutical manufacturing to ensuring hygiene in food processing plants, these wipes are indispensable. Some of the industries that rely on cleaning wipes include:

- Electronics manufacturing: Static electricity is a big problem in this industry. Anti-static wipes help keep static at bay while cleaning dust and particles off sensitive electronic components.

- Food processing plants: Hygiene is paramount in these facilities. Food-grade sanitizer wipes are used to clean surfaces and equipment, ensuring that the food produced is safe for consumption.

- Automotive repair shops: From oil and grease spills to brake dust and other particulates, the potential for contamination in an automotive repair shop is high. Industrial cleaning wipes are utilized extensively in these environments to ensure a clean, safe workspace by regularly wiping down tools and equipment.

- Maintenance: In maintenance fields, from HVAC to general facility upkeep, cleaning wipes are used to remove dust, dirt, and grease from tools and equipment. This helps promote the longevity and optimal performance of these items.

- Aerospace: The aerospace industry has stringent cleanliness standards. Specialized wipes are used to clean and maintain aircraft components, helping to prevent malfunctions and ensure the safety and reliability of flights.

- Printing: In the printing industry, cleaning wipes are used to remove excess ink and debris from printing machines. This maintains the quality of the prints and prolongs the life of the machinery.

- Marine: In marine environments, cleaning wipes are used for a variety of tasks, from cleaning ship components to maintaining cleanliness in living and eating areas. These wipes help prevent corrosion and the spread of bacteria in harsh marine conditions.

- Laboratories: Laboratories require very high levels of cleanliness to ensure accurate results. Lab-grade cleaning wipes are used to clean lab equipment and surfaces, helping to prevent cross-contamination and ensure the accuracy of experiments.

For each of these applications, there’s a suitable type of industrial cleaning wipe. Electronics manufacturing often uses anti-static wipes, while food processing plants require food-grade sanitizer wipes. And, as mentioned before, highly absorbent wipes are an excellent disposable cleaning option for automotive repair shops.

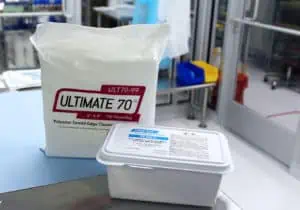

Why Quality Matters at High-Tech Conversions

At High-Tech Conversions, we understand that quality is not just a requirement but the key to your operational success. Our team is dedicated to providing top-tier industrial wipes tailored to your needs and applications. The superior quality of our products ensures effective cleaning and maintenance, contributing to the durability of your equipment and a safer workplace. By choosing our high-quality wipes, you can minimize disruptions and enhance productivity in your daily operations.

Knowing how to choose the right industrial cleaning wipes for your specific application reflects your ability to recognize and understand the specifics of your professional sector. Whether you’re in the automotive industry, running a pharmaceutical manufacturing facility, or managing a commercial cleanroom, there are quality industrial wipes designed to meet your needs.